Dr. C. Ryan Oliver

Department of Internal Medicine and Bioengineering, University of Michigan

Tuesday, 9/27/2016 at 11:30am

Boulevard Room at Pierpont Commons

An additive manufacturing approach to printing cells and microbeads within digitally addressed hydrogel matrices

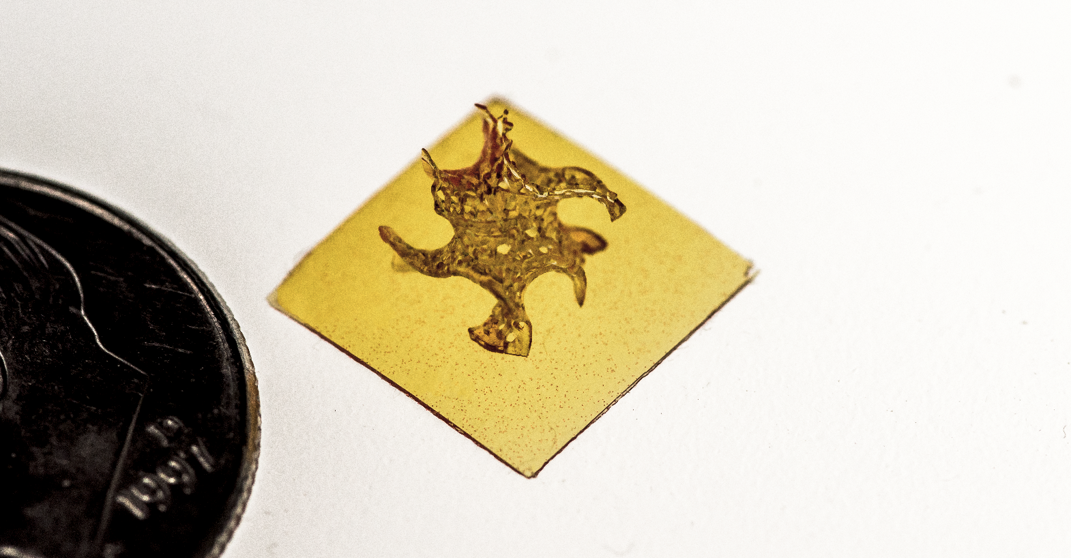

Rapid prototyping of new hydrogel-based structures, including tissue scaffolds, organs-on-chip, and hybrid bioelectronic materials, requires flexible fabrication techniques capable of positioning multiple materials in 2D and 3D with micro-scale resolution and accuracy. Despite their impressive accomplishments, current methods for micro-scale additive manufacturing are limited to a single material (e.g. projection micro stereolithography) or require sequential or parallel use of multiple nozzles to deposit different materials. An alternative approach would be to digitally place discrete building blocks, e.g. microbeads or cells within a 3D matrix such as a hydrogel. This strategy would enable control over both the global and local properties of the fabricated part.

In this talk I will be discussing progress in the development of a new micro-scale additive manufacturing process (first realized while in the Mechanosynthesis group), enabling local and regional control over the placement of microscale objects in a 3D matrix. This method uses feedback from a high-speed machine vision system to guide the placement of microscale objects using a digital light processing device (DLP). I will also discuss the potential applications of this approach and challenges including clumping, clogging and digital errors.

These results show promise to enable on-demand additive manufacture of soft structures with digital three-dimensional placement of discrete building blocks.

In this talk I will be discussing progress in the development of a new micro-scale additive manufacturing process (first realized while in the Mechanosynthesis group), enabling local and regional control over the placement of microscale objects in a 3D matrix. This method uses feedback from a high-speed machine vision system to guide the placement of microscale objects using a digital light processing device (DLP). I will also discuss the potential applications of this approach and challenges including clumping, clogging and digital errors.

These results show promise to enable on-demand additive manufacture of soft structures with digital three-dimensional placement of discrete building blocks.